From Discovery to Market: Using Data Science to Improve Innovation in Consumer Crops

What if we could take the guess work out of field work?

In a form of data science Moneyball, Pairwise is using sophisticated analytical methods to understand how plants are growing in the physical environment. Plant phenotyping often has been conducted subjectively, with root length measured by the naked eye or plant height benchmarked off of a jeans pocket. This data often was written down manually before data entry, inviting errors and lengthening both compilation and analysis time.

BOB in action.

Enter BOB, short for “Berries On Board”, Pairwise’s own mobile imaging cart that roves the Rubus collaboration site at Plant Sciences, Inc (PSI) in Watsonville, CA. BOB allows the team to conduct high-throughput, image-based phenotyping, capturing traits such as plant or leaf size, uniformity (essential for mechanical harvest), and plant height. As part of the Rubus collaboration, also known internally as the GWAS project, BOB captures GPS position, and multiple color and depth images of all plants grown every week. These images are then fed into machine learning models that automatically extract plant height, plant robustness, and flowering data, which in-turn are input into statistical models linking genomics to the phenotypes extracted.

“Data Science as a field blends domain-specific knowledge, quality data, statistical algorithms and computational horsepower to make it easy to answer questions that we care about,” says Aabid Shariff, Data Science Lead for Pairwise. “The algorithms when validated and put together carefully allow us to go from data to answers quickly. Image-based phenotyping is a domain that benefits from data science approaches because of the ability to collect vast, quality data with imaging systems like BOB.”

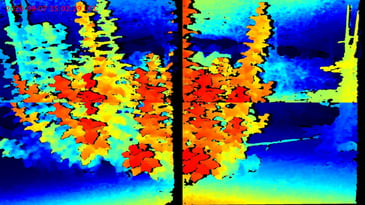

False color depth image taken by BOB on-site at our public/private rubus collaboration.

to our academic collaborators and internally into the cloud-based informatics platform Benchling.

In order to design BOB, the team thought of ways to build a modular, re-usable and easily repairable imaging platform and conducted the machining of the hardware, using CAD design & prototyping techniques. The team also developed front-end software tools to make it easy for our collaborators across the country to capture, label and ultimately stream data to the cloud.

BOB is just one example of how the Pairwise team is developing innovative ways to use emerging technology to conduct vital product research.